Multilayer HDI PCB: PCB Assembly Services for Industrial Electronics by FastTurnPCB

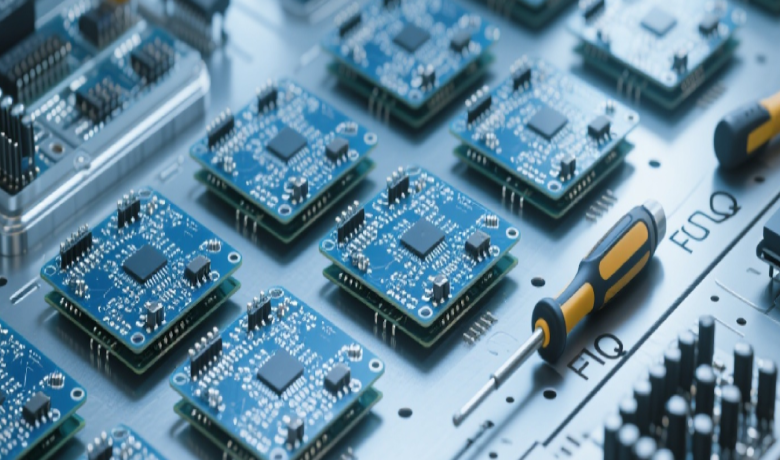

Industrial electronics demand robust, precise, and reliable solutions. From automation systems to control panels, robotics, and energy management devices, every component must perform flawlessly under strict operational requirements. FastTurn PCB has become a trusted partner for industrial electronics manufacturers by offering comprehensive PCB assembly services and advanced multilayer HDI PCB solutions. With decades of expertise and a commitment to quality, FastTurnPCB supports businesses worldwide in delivering high-performance electronic products efficiently and reliably.

The Importance of PCB Assembly in Industrial Electronics

Industrial electronics operate in demanding environments where failure is not an option. Whether it’s a factory automation system or an industrial IoT device, the reliability of a printed circuit board can determine the overall performance of the product. PCB assembly is a critical stage, integrating electronic components onto the board with precision, quality, and durability.

FastTurnPCB’s experience in multilayer HDI PCB assembly ensures that even the most complex industrial electronics are manufactured to exacting standards, supporting both high reliability and long service life.

Advanced Multilayer HDI PCB Capabilities

Industrial applications often require boards with multiple layers, high routing density, and advanced interconnections. FastTurnPCB specializes in multilayer hdi pcb fabrication and assembly, providing:

- Microvias and fine-pitch connections

- Blind and buried vias for optimized routing

- Multiple-layer stackups for complex designs

- High-density component placement

These capabilities allow manufacturers to develop compact, high-performance boards capable of handling sophisticated industrial applications.

Comprehensive PCB Assembly Services

FastTurnPCB offers end-to-end assembly services designed to support industrial electronics manufacturers at every stage, from prototyping to high-volume production.

Surface Mount Technology (SMT)

SMT assembly is the backbone of modern PCB manufacturing. FastTurnPCB employs high-precision pick-and-place machines capable of handling fine-pitch components, BGAs, and other complex surface-mount devices, ensuring reliable performance for industrial electronics.

Through-Hole and Mixed Technology Assembly

Some industrial designs require a combination of SMT and through-hole components for enhanced mechanical strength or specialized functionality. FastTurnPCB provides mixed-technology assembly to meet these requirements with precision and efficiency.

Rigid, Flex, and Rigid-Flex Assembly

Many industrial devices utilize flexible or rigid-flex boards to save space and increase durability. FastTurnPCB’s assembly capabilities accommodate all types of boards, ensuring consistent quality across rigid, flexible, and multilayer HDI PCB designs.

Rigorous Testing and Quality Control

Reliability is crucial in industrial electronics, where failure can result in costly downtime or safety issues. FastTurnPCB implements comprehensive testing procedures to ensure every PCB assembly meets the highest standards:

- Automated Optical Inspection (AOI): Detects visual defects and placement errors

- Electrical Testing: Verifies continuity, shorts, and overall functionality

- X-ray Inspection: Confirms hidden solder joints, BGA, and microvia integrity

- Functional Testing: Simulates real-world operating conditions for performance verification

By combining advanced testing with strict process controls, FastTurnPCB guarantees that industrial electronics assemblies are robust, reliable, and ready for demanding environments.

See also: Boost Website Performance Through Smart Web Design Techniques

Rapid Prototyping for Industrial Electronics

Fast product development is critical for staying competitive. FastTurnPCB offers rapid prototyping services that allow manufacturers to quickly test, validate, and iterate designs. This capability is especially valuable for multilayer HDI PCB projects, where complexity can otherwise delay production.

Prototyping with FastTurnPCB reduces development cycles, allowing manufacturers to bring innovative industrial products to market faster while maintaining high quality standards.

Turnkey PCB Solutions

FastTurnPCB provides turnkey services that combine design review, component sourcing, assembly, testing, and logistics into a single, seamless workflow. This integrated approach eliminates the inefficiencies and risks associated with managing multiple vendors.

Benefits of turnkey PCB services include:

- Streamlined communication and project management

- Faster time-to-market

- Reduced risk of errors and component mismatches

- Cost-effective manufacturing

- Scalable solutions for both small and large production runs

By offering turnkey solutions, FastTurnPCB ensures that industrial electronics projects proceed smoothly from concept to delivery.

Serving Diverse Industrial Sectors

FastTurnPCB’s expertise supports a wide range of industrial sectors:

- Factory Automation: PLCs, motor controllers, sensors

- Energy Management: Power supplies, monitoring devices

- Robotics: Control systems, actuators, and feedback devices

- Industrial IoT: Data acquisition, communication modules, and control boards

- Telecommunications: Network control boards and communication modules

Each sector has specific requirements for performance, reliability, and compliance, which FastTurnPCB meets through advanced multilayer HDI PCB assembly capabilities.

Engineering Support and Design Optimization

FastTurnPCB goes beyond standard assembly services by providing engineering support to optimize designs for manufacturability and assembly. This includes:

- Design-for-Manufacturability (DFM) analysis

- Component placement optimization

- Thermal management recommendations

- Yield improvement suggestions

By collaborating with manufacturers at the design stage, FastTurnPCB minimizes risks, reduces production errors, and enhances the overall reliability of industrial electronics assemblies.

Global Support and Logistics

Supporting industrial electronics manufacturers worldwide requires robust logistics and supply chain management. FastTurnPCB provides:

- Global shipping solutions

- Inventory management and repeat-order fulfillment

- Custom packaging for sensitive components

- Full traceability and documentation for compliance

This global reach ensures that industrial electronics assemblies are delivered on time, securely, and ready for deployment.

Why Manufacturers Choose FastTurnPCB

FastTurnPCB has become the go-to partner for industrial electronics manufacturers due to its:

- Expertise in multilayer HDI PCB fabrication and assembly

- Comprehensive turnkey services from design to delivery

- Fast prototyping and rapid production capabilities

- Rigorous quality assurance and testing

- Global support for manufacturers of all sizes

- Cost-effective and scalable manufacturing solutions

These advantages make FastTurnPCB a trusted partner for industrial electronics projects worldwide.

Conclusion

High-quality PCB assembly is a critical component of industrial electronics manufacturing. FastTurn PCB offers advanced multilayer HDI PCB fabrication, turnkey assembly services, and global support that empower manufacturers to develop innovative, reliable, and high-performance products.

By choosing FastTurnPCB, industrial electronics companies gain a partner capable of delivering exceptional quality, rapid turnaround, and comprehensive support from initial design through final delivery.

For industrial electronics manufacturers seeking reliable PCB assembly solutions and advanced HDI capabilities, visit FastTurn PCB to explore their services and capabilities.