Innovations in CNC Swiss Machineing

Introduction to CNC Swiss Machineing

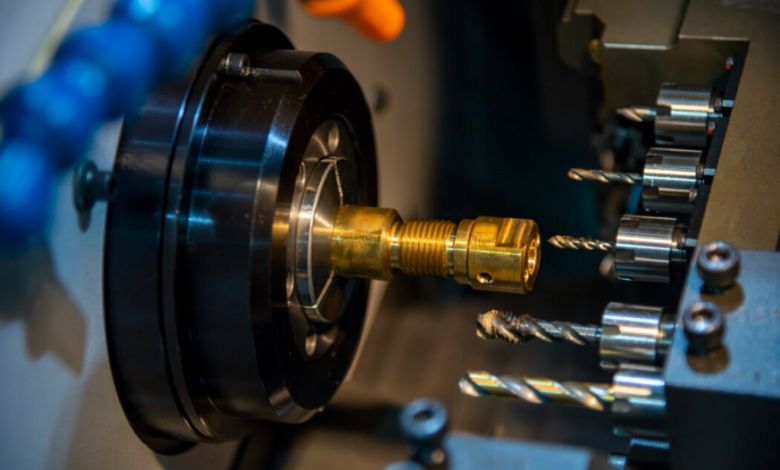

CNC swiss machineing is a highly precise manufacturing process used to create small and complex components. It differs from traditional lathes because the material is guided close to the cutting tool, allowing for high accuracy and minimal deflection. Industries like medical, aerospace, automotive, and electronics heavily rely on this technology for high-quality, consistent results.

Core Features of CNC Swiss Machineing

Sliding Headstock System

The sliding headstock design allows the material to move in perfect alignment with cutting tools. This minimizes vibrations and ensures consistent dimensional accuracy, especially when machining long or thin components.

Multi-Axis Machining

Modern CNC swiss machines often include multi-axis capabilities, enabling simultaneous turning, milling, and drilling in a single setup. This reduces production time and enhances efficiency while maintaining tight tolerances.

Automatic Tool Management

Automated tool changers increase productivity by reducing manual intervention. Tools can be switched quickly during operations, ensuring continuous machining and reducing the risk of errors.

Advantages of CNC Swiss Machineing

Superior Precision

Because the workpiece is supported closely by the guide bushing, even intricate designs can be manufactured with minimal deviation. This makes it suitable for parts that require extreme accuracy, such as surgical instruments or aerospace components.

Increased Efficiency

Combining multiple machining operations in one setup reduces handling time and production cycles. This approach is particularly advantageous for high-volume manufacturing where time and precision are critical.

Versatile Material Handling

CNC swiss machineing can process a variety of materials including stainless steel, brass, aluminum, titanium, and certain plastics. This versatility makes it ideal for diverse industrial applications.

Cost-Effective Production

Although initial investment may be high, cnc swiss machineing reduces scrap rates and rework, leading to long-term savings. Fewer errors and higher efficiency result in lower overall production costs.

Choosing the Right CNC Swiss Machineing Provider

Experience and Expertise

Selecting a provider with extensive experience ensures optimized machining strategies and accurate results. Expertise is crucial for handling complex designs and materials.

Modern Equipment

Providers with up-to-date multi-axis machines and digital controls are better equipped to handle precision components efficiently. Advanced machinery ensures consistent quality and faster production.

Rigorous Quality Control

Reliable providers implement strict inspection protocols to maintain consistent quality across batches. This guarantees that all components meet required specifications.

Flexibility and Adaptability

A competent provider can manage urgent orders, adapt to design changes, and maintain production quality, which is important for dynamic manufacturing environments.

Applications of CNC Swiss Machineing

Medical Industry

CNC swiss machineing is extensively used in producing surgical instruments, implants, and diagnostic components, where precision is non-negotiable.

Aerospace Components

High-precision components such as engine parts and structural elements are produced using cnc swiss machineing, meeting strict safety and performance standards.

Automotive Manufacturing

Engine parts, fuel system components, and other critical automotive elements benefit from the accuracy and efficiency of cnc swiss machineing.

Electronics and Connectors

Miniature parts for electronic devices, including connectors and housings, are manufactured with cnc swiss machineing, ensuring reliable performance in compact designs.

See also: Ways SINTRONES’ NVIDIA Jetson AGX Orin Revolutionizes Smart Traffic Technology

Emerging Trends in CNC Swiss Machineing

Integration of Automation

Robotic systems integrated with cnc swiss machineing reduce manual labor, increase production speed, and enhance consistency in large-scale manufacturing.

Hybrid Manufacturing

Combining CNC swiss machineing with additive manufacturing allows for complex shapes and reduces material waste, providing innovative solutions for challenging designs.

Sustainable Practices

Manufacturers are focusing on energy-efficient operations and environmentally friendly materials, aligning high-precision manufacturing with sustainability goals.

Simulation and Digital Twin Technology

Digital simulations of machining processes allow manufacturers to predict and optimize performance before actual production, minimizing errors and increasing efficiency.

Conclusion

CNC swiss machineing has become an essential technology for industries requiring precise, small, and complex components. Its advantages include superior accuracy, efficiency, and versatility across materials. Selecting experienced providers with modern equipment and robust quality control ensures reliable results. As the technology continues to evolve, cnc swiss machineing remains a critical tool for innovation and high-quality manufacturing across medical, aerospace, automotive, and electronics sectors.